Before the mid-1960s, 70% of natural diamonds in the Soviet Union were used in industry for the production of diamond micropowder, diamond grinding paste and diamond tools after crushing. Since the industrial scale production of synthetic diamond, the diamond micropowder produced by natural diamond has been gradually replaced. As we all know, the grinding capacity of diamond is higher than that of other abrasives. Therefore, diamond micro-powder as a kind of superhard abrasive, its superior grinding ability, is highly valued by industrial developed countries.

Diamond wire saw cutting technology has the advantages of high efficiency, low loss and large size cutting ability, and has been fully applied to the photovoltaic new energy field, while it has the basic conditions for semiconductor silicon material cutting field such as integrated circuit chips, the future once the large-scale application, diamond powder market demand will be greatly increased.

In addition to photovoltaic, consumer electronics and other fields, diamond micro-powder is also used in LED sapphire, magnetic materials, ceramic materials and other fields, including 3C products, LED semiconductor lighting, new energy vehicles and other industries. In addition, the functional application market of diamond in the fields of light, electricity, sound and heat has begun to emerge, and the industrialization curtain is about to open. Including diamond thermal conductivity materials, electrode materials, wear-resistant materials, photoelectric devices and biomedical materials, will also form a huge market demand.

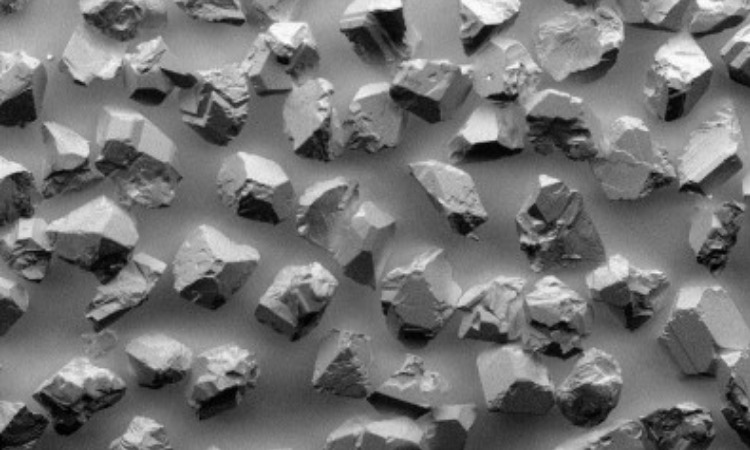

In order to refine the structure of diamond powder, improve the self-sharpness of abrasive, effectively reduce cutting damage, and improve surface processing quality, the continuous transformation and upgrading of the downstream market have put forward higher and higher requirements for the particle size, impurities, morphology and surface properties of diamond powder. In the future, diamond powder will develop in the direction of ultra-fine, ultra-pure, ultra-fine and surface modification.