Diamond powder is widely used in the semiconductor industry, whether it is used in abrasive, optical lens grinding, chip manufacturing or packaging materials, its excellent performance and environmental advantages make it an important position in semiconductor manufacturing. With the development of science and technology, diamond micro-powder will play a more important role in the future semiconductor industry.

Advantages of diamond powder in semiconductor industry

1.High hardness: The hardness of diamond powder is extremely high, which can effectively cut and grind various materials, including semiconductor materials.

2.High thermal conductivity: diamond powder has excellent thermal conductivity, which can effectively dissipate heat and improve the performance and stability of semiconductor equipment.

3.Environmental protection and pollution-free: The grinding and polishing process of diamond powder is relatively environmentally friendly and has little impact on the environment.

4.Efficient production: The excellent performance of diamond powder greatly improves the production efficiency and reduces the production cost.

Application of diamond powder in semiconductor industry

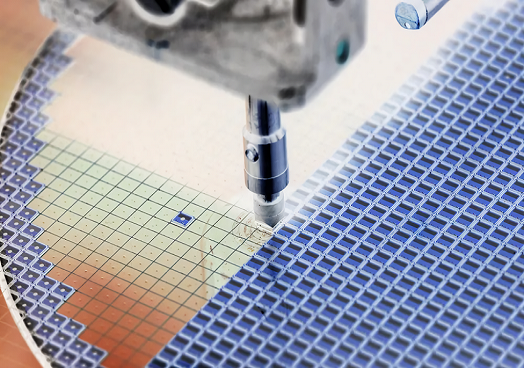

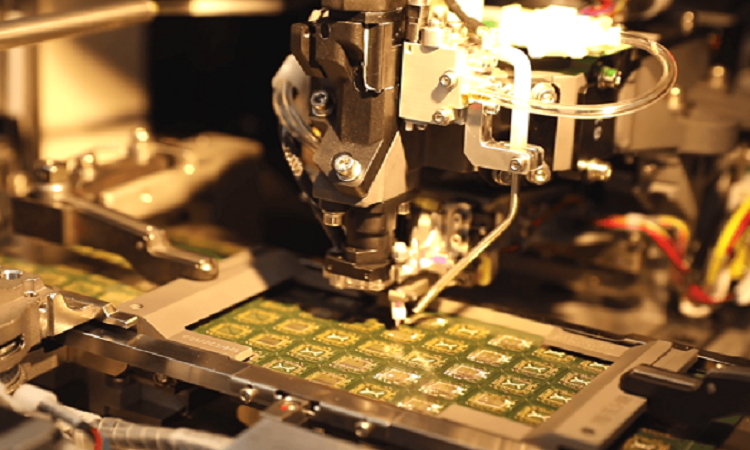

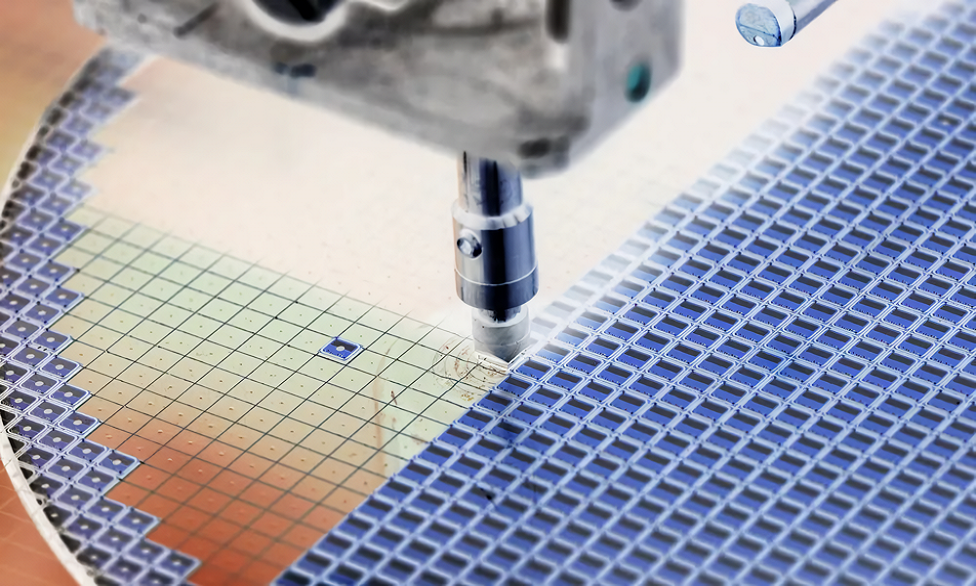

1.Abrasive: diamond powder is used for precision cutting and grinding of semiconductor wafers, which can effectively reduce the difficulty of cutting and grinding and improve production efficiency.

2.Optical lens grinding: Diamond powder can also be used for fine grinding of the optical lens surface to improve the light transmission and clarity of the lens.

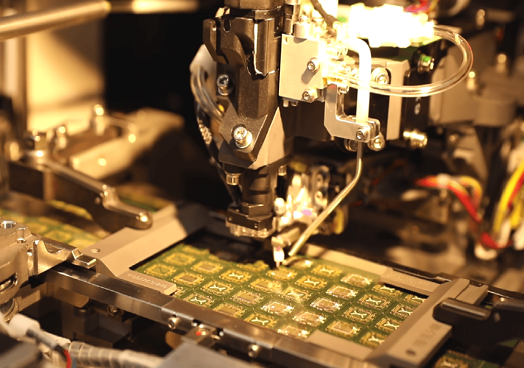

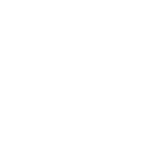

3.Chip manufacturing: Diamond powder polishing agent can be used in the final polishing step of semiconductor chips to ensure smooth chip surface and improving chip performance.

4.Semiconductor packaging materials: diamond powder can also be used for grinding and polishing of semiconductor packaging materials to improve packaging quality.