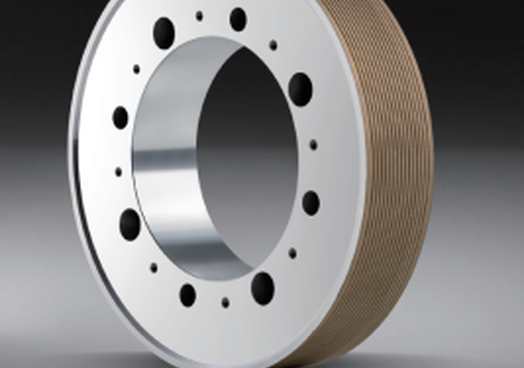

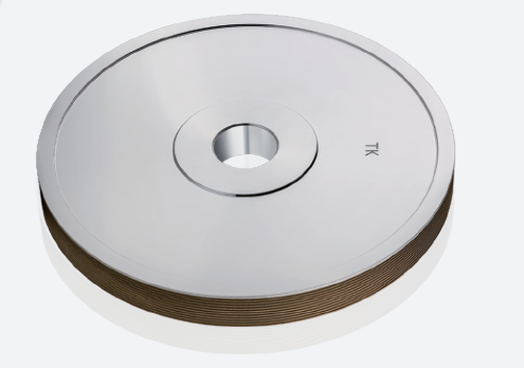

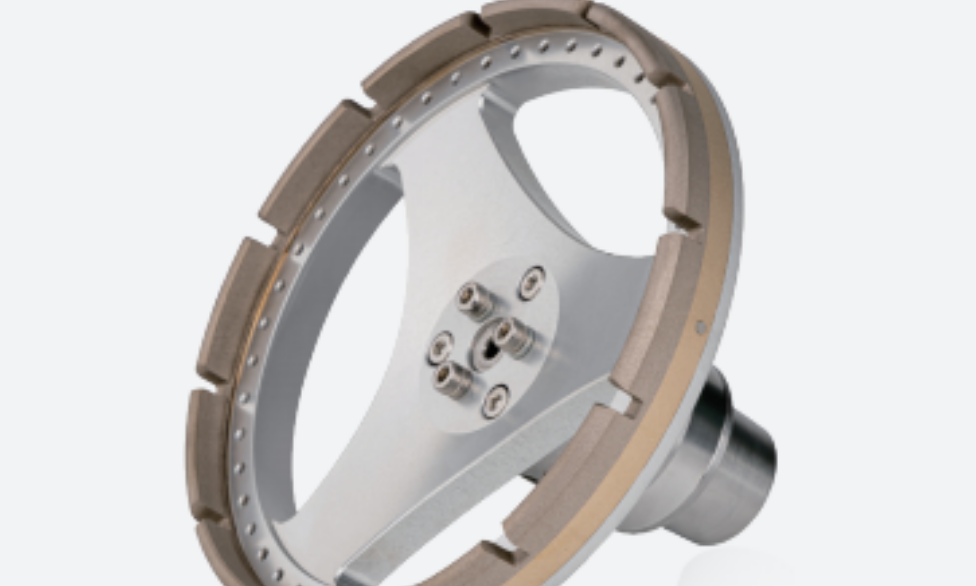

Diamond grinding wheel is an effective precision machining method for grinding hard and brittle materials by using diamond abrasive as raw material and metal powder, resin powder, ceramic and electroplated metal as bonding agents. It has strong grinding ability, good wear resistance, long service life, small grinding force, low grinding temperature, no surface burns, no cracks and tissue changes, good surface quality, and high grinding efficiency, so it has been widely used in recent years, but it is difficult to meet the higher requirements of ultra-precision machining in geometric shape accuracy and surface roughness. Diamond powder grinding wheel is generally made of diamond powder with particle size of w40-w5 as abrasive, using resin, ceramics, metals such as copper, fiber cast iron and so on as bonding agent sintered.

Diamond powder grinding wheel can obtain very low surface roughness due to the fine particle size of its powder abrasive, and high grinding accuracy can be obtained by grinding on the precision grinder or ultra-precision grinder, which is an ideal micro-nano ultra-precision machining method.

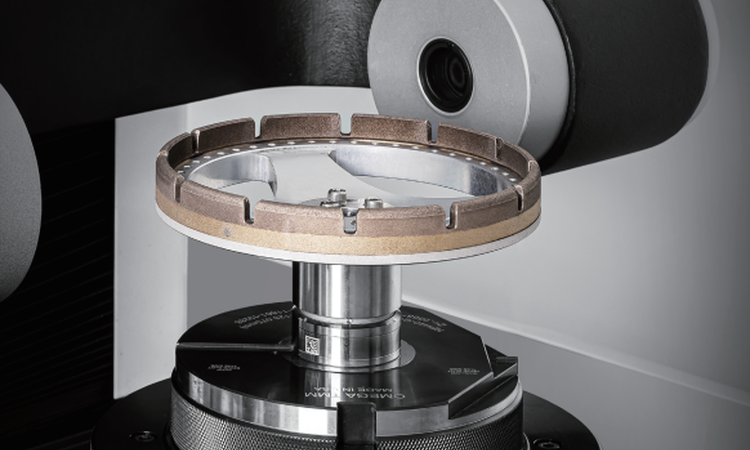

Diamond powder grinding wheel due to the abrasive grain size is very fine, chip space is very small, chips are easy to clog, therefore, in addition to general dressing, but also to carry out on-line dressing, in order to ensure the normal grinding and processing quality.